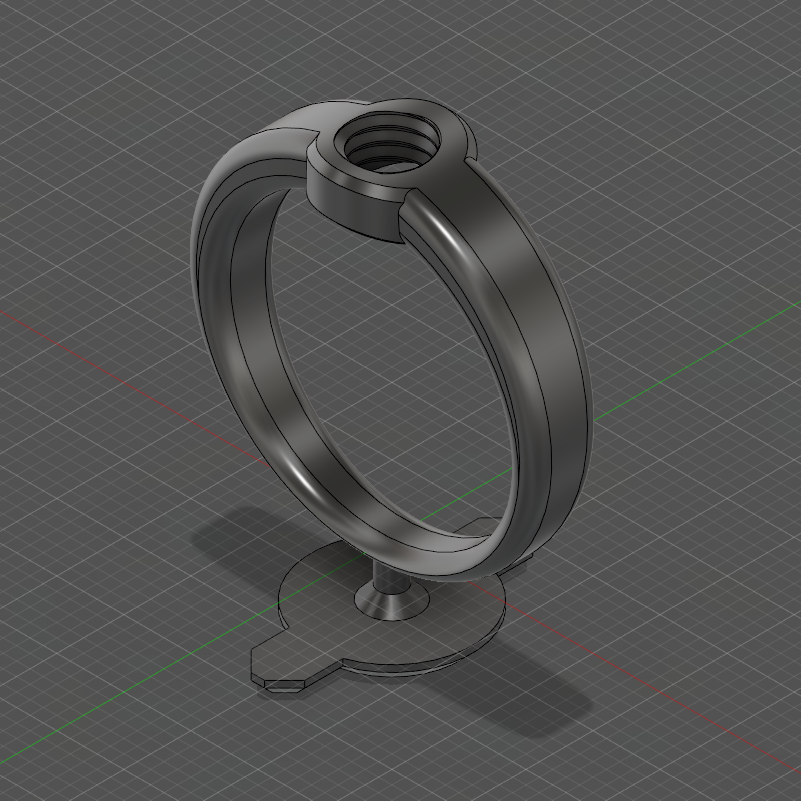

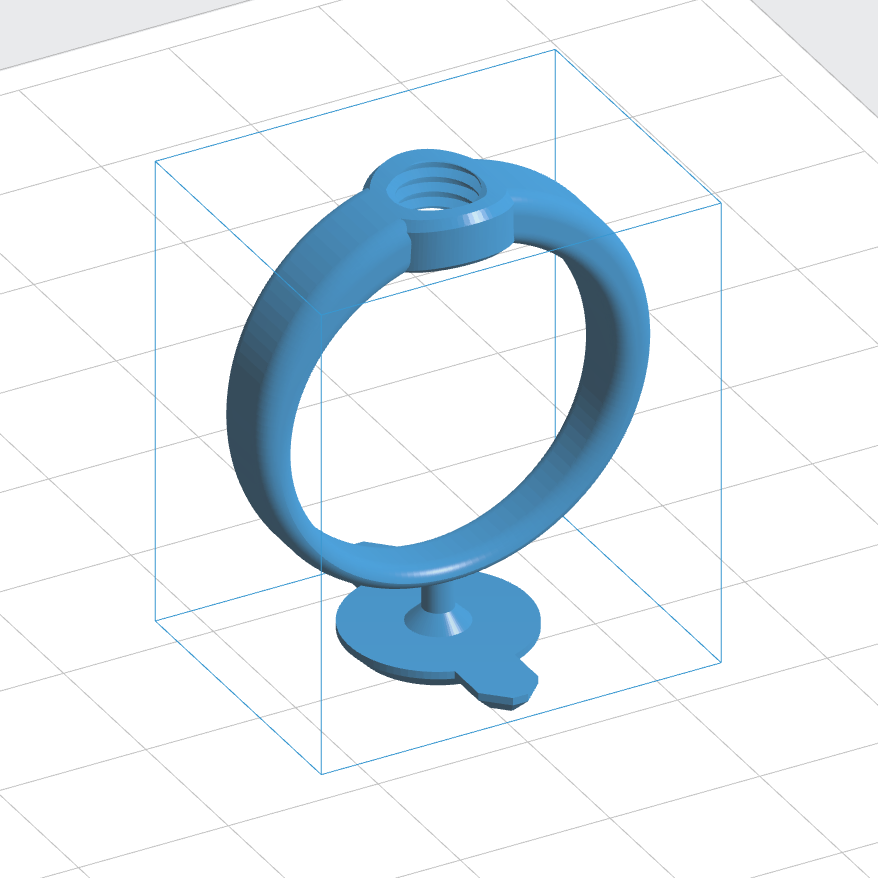

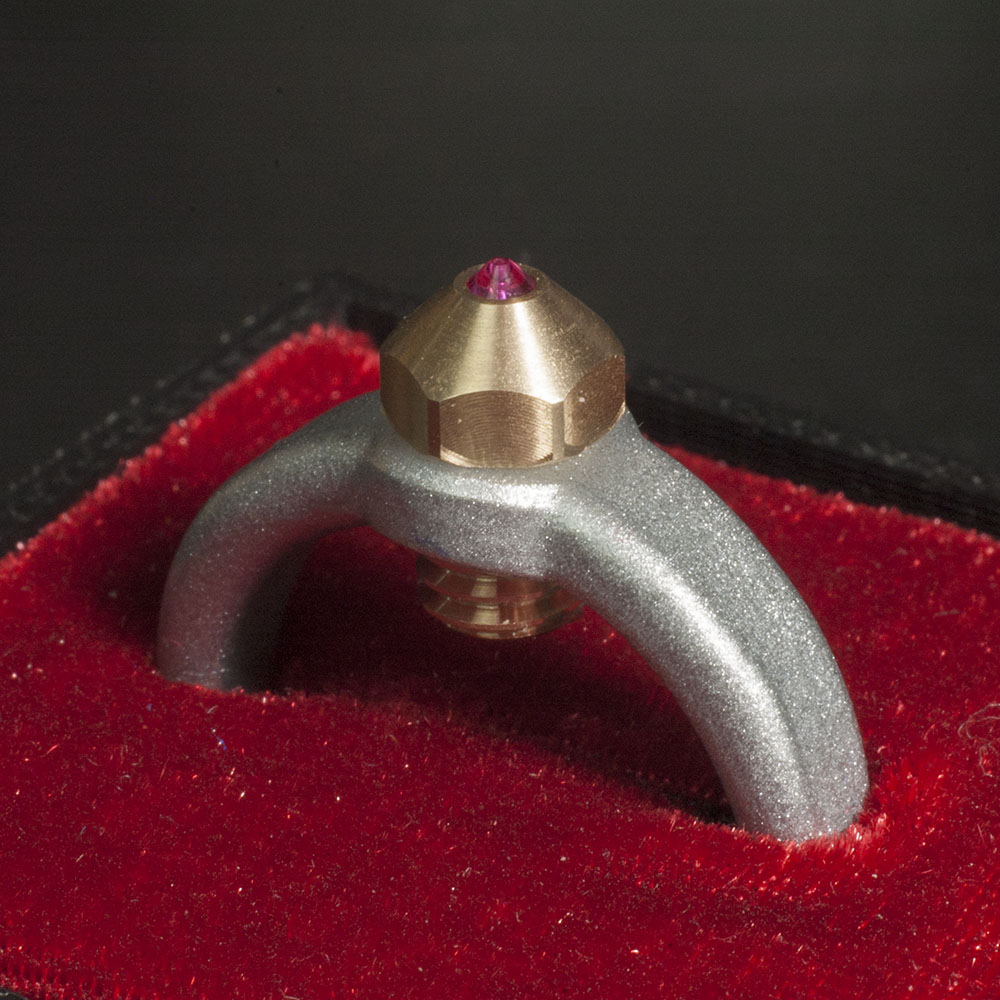

I keep being impressed by that ring every time I check this thread Meduza, if I had more time I would deliver all of them in such packaging

Those of you who expressed interest in testing a nozzle in this thread have been contacted by me now.

People in the US will have to wait slightly longer than European users.

If you wrote in the thread and did not express interest, but still want to test a ruby nozzle, tell me and I will see what I can do.

I don't have any particular demands on the testers performing tests with this batch.

Just print as usual, or do whatever you want with the nozzle, and provide feedback (both good and bad things).

What I am particularly interested in for this batch is:

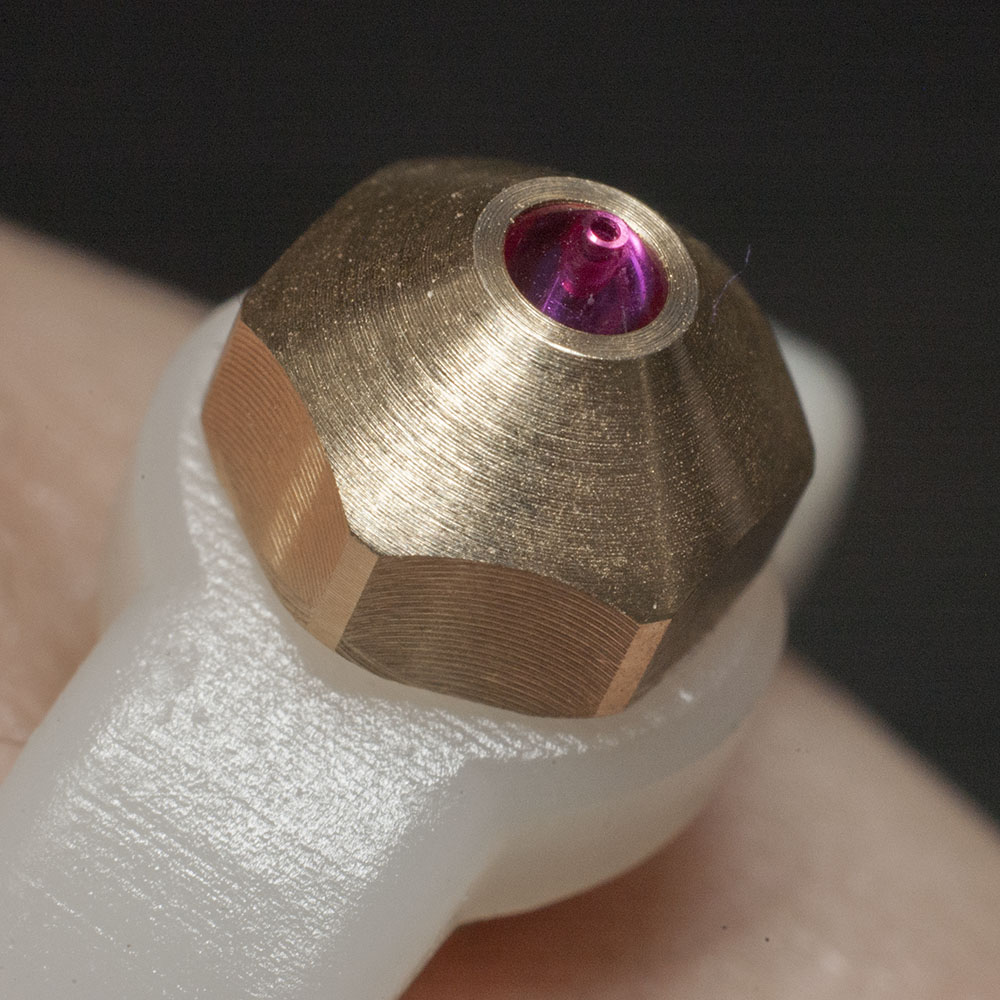

- Thermal conductivity issues, particularly for the 3 mm version (which has a bit lower conductivity than desired, which will be corrected for next batch)

- Will the ruby stay in place? (The fixing is a bit minimalistic on this batch, will be improved on the next version)

- Any problems with leaks?

Of course I am also interested in printing quality observations and anything that can wear the ruby.

Recommendations for users:

- Most materials appears not to wear the ruby at all. However, GMASS-tungsten filament and cleaning the nozzle with scotch-brite does wear it.

I don't mind if you do things that wears the nozzle, it is actually interesting for me, but I can not provide unlimited numbers of free nozzles

- Do not over-tighten the nozzle! It should take about 3 Nm before it breaks compared to 5 Nm for normal nozzles, but 0.25 Nm is normally enough for it not to leak (use the printable torque wrench).

- If you clog the nozzle and use a needle to clear it, be careful not to bend the needle, or this can happen:

(Next batch will be a bit stronger)

EDIT: One more thing:

I have tested the all the nozzles before shipping, so there will be some PLA left in most of them. If I used ABS I tried to remove it before shipping.

Some of them has been used a bit longer than others since I use them for printing things I actually need rather than printing robots

So your nozzle might not look as clean as the one in Meduzas picture, but you will have to live with that